Industrial Coffee Mill Guide: Increase Effectiveness and High Quality

In the competitive landscape of coffee manufacturing, picking the right industrial coffee grinder plays a critical function in enhancing both performance and item high quality. Recognizing the nuances of various mill types and crucial attributes-- such as personalized work setups and robust building-- can dramatically influence the final flavor profile of the coffee. Moreover, the optimization of the grinding procedure, combined with diligent upkeep, is necessary for maintaining efficiency with time. As we discover these important aspects, it becomes noticeable that the implications prolong beyond plain equipment option, impacting total service success in manner ins which warrant closer exam.

Comprehending Grinder Kinds

When choosing an industrial coffee mill, comprehending the different kinds available is critical for enhancing both taste removal and operational efficiency. The two main types of grinders are blade mills and burr mills.

Ultimately, picking the best sort of mill is integral to keeping high quality and performance in coffee production, making it imperative for services to buy high-grade burr grinders for optimum outcomes.

Key Functions to Consider

Picking an industrial coffee grinder needs mindful factor to consider of several essential features that can substantially affect both performance and the general coffee experience. Among the main elements to evaluate is the grinding mechanism. Burr grinders are typically liked over blade grinders, as they supply a regular work size, which is important for optimal extraction and taste.

An additional vital attribute is the grinder's ability. A versatile grinder with multiple setups enables you to customize the grind size to different brewing techniques, improving the coffee's taste profile.

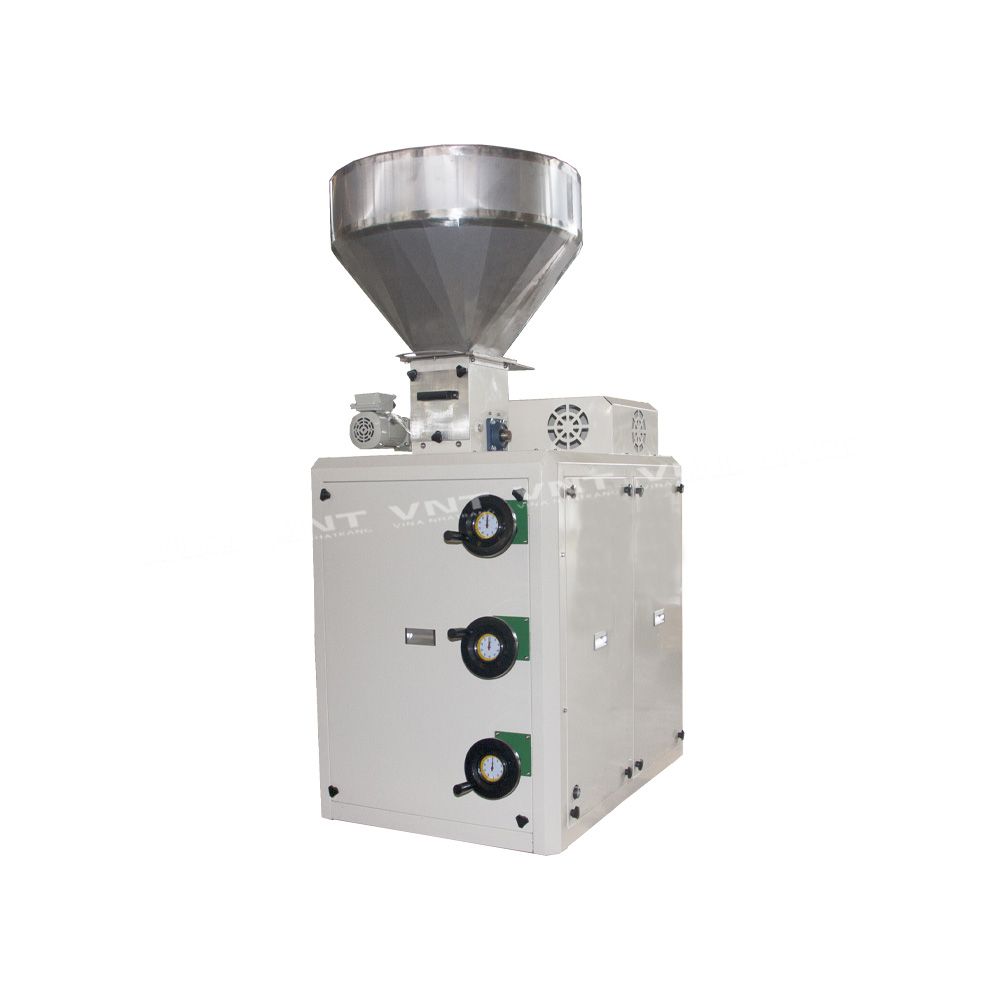

The construction product additionally plays a duty in resilience and maintenance. Stainless steel components typically provide durability and are much easier to clean up, which is important for keeping hygiene standards. Assess the grinder's noise level, especially in an active coffee shop or production environment, where extreme noise can be turbulent. Buying a grinder that balances these attributes can significantly boost both functional performance and the top quality of the coffee served.

Optimizing Grinding Process

To achieve the finest outcomes in coffee prep work, optimizing the grinding process is important. The grind size dramatically affects removal, flavor, and general top quality of the brewed coffee.

Furthermore, keeping track of the grinding Web Site speed can enhance the procedure. Slower grinding frequently creates much less warm, preserving delicate tastes and scents. Alternatively, much faster grinding might create excessive warmth, negatively influencing the coffee's quality.

Upkeep and Treatment Tips

Appropriate maintenance and care of industrial coffee grinders are vital for making sure optimum performance and longevity. Normal cleansing is the structure of maintenance; deposit accumulation can impact taste and grinding effectiveness. It is a good idea to clean up the mill after each usage, cleaning down the outside and removing any type of coffee grounds from the burrs.

Additionally, check the grinding burrs for deterioration. Dull burrs can compromise grind consistency, so they must be replaced as necessary. Industrial Coffee Grinder. Regularly adjusting the mill is additionally vital, as this maintains the preferred work size for different brewing techniques

Lubrication of relocating parts must be executed according to the producer's specs, as this decreases friction and extends the life of the equipment. It is important to use food-grade lubes to make sure safety and conformity with health and wellness laws.

Finally, maintain the mill in a completely dry and secure environment to stop rust and deterioration. By sticking to these maintenance and care suggestions, drivers can enhance the effectiveness of their industrial coffee mills while ensuring top quality result and expanded functional life.

Return on Investment Evaluation

Examining the roi (ROI) for industrial coffee mills is critical for businesses looking for to enhance their coffee production capabilities. An extensive ROI analysis assists determine the economic feasibility of buying premium grinders, permitting businesses to weigh the first prices against prospective gains.

Assess the purchase cost of the mill, including installation and any essential alterations to existing framework. High-performance mills usually lead to next page reduced grinding time and increased throughput, which can substantially boost productivity.

Additionally, consider the effect on product high quality. Industrial Coffee Grinder. Superior grinders yield an even more constant grind size, which can improve flavor accounts and consumer complete satisfaction, ultimately driving sales. By increasing the top quality of the last product, businesses can validate higher pricing, resulting in raised income

Verdict

In recap, a commercial coffee grinder plays a critical role in enhancing both effectiveness and item high quality within coffee production. Inevitably, the calculated financial investment in a trusted mill contributes dramatically to boosted income and competition in the coffee market.

In the competitive landscape of coffee manufacturing, choosing the appropriate industrial coffee grinder plays a pivotal function in boosting both effectiveness and item top quality. The 2 main kinds of grinders are blade grinders and burr mills. Within the burr grinder category, there are flat burr mills and conical burr mills, each with its advantages. Burr mills are typically chosen over blade mills, as they provide a constant grind dimension, which is vital for optimal removal and taste.

In summary, an industrial coffee grinder plays an essential duty view it now in improving both efficiency and product top quality within coffee manufacturing.